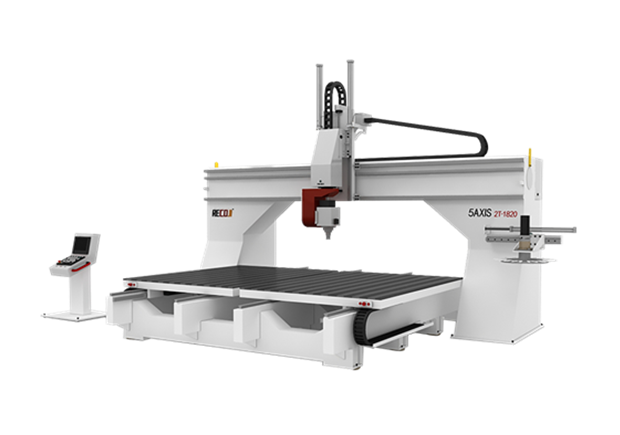

It is widely used in the industry of solid wood furniture, mold making, edge milling and chamfer of household appliances, bathroom, PVC/PP/PE, ABS, rubber, plastic polyurethane, carbon fiber and other composite material. It can finish slotting, chamfer, milling, grooving, etc.

This machine is specialized in cutting, chamfer, trimming, drilling, polishing, engraving on marble, quartzite, granite, wood, composite material etc. It is widely used in the industry of kitchen cabinet countertop, bathtub, lavabo, etc

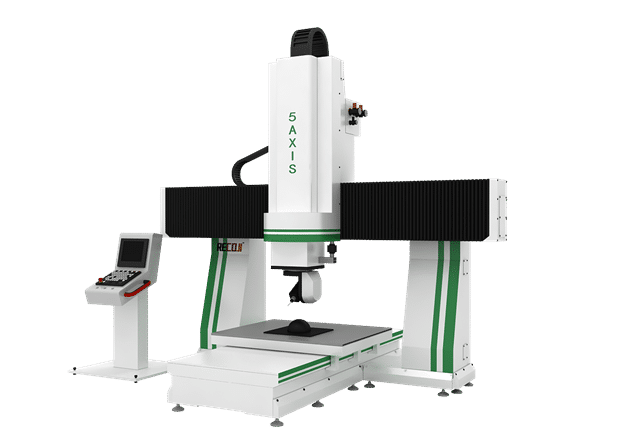

It can be applied to solid wood furniture, mold processing, home appliance trimming, bathroom bags, PVC/PP/PE, ABS, rubber, polyurethane, glass fiber, carbon fiber and other composite materials for grooving, chamfering, blasting, Multi-process, multi-angle, high-precision and high-efficiency machining such as hook grooves.

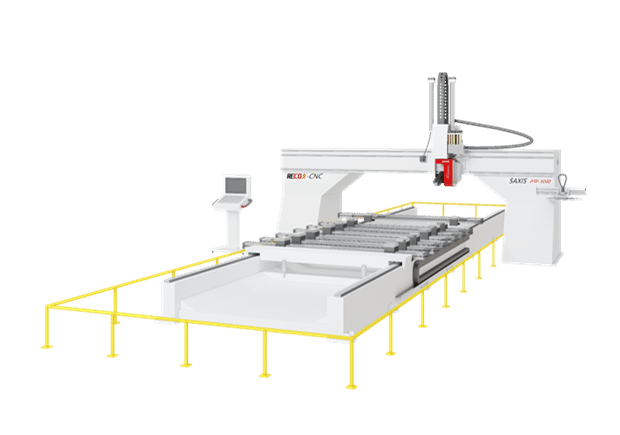

This machine is very suitable for processing such as large sculpture, large mold manufacturing, green energy industry, shipbuilding industry or aviation industry, etc.

Covers18countries

accumulate208customer cases

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

Contact Us

Contact Us