Current Location:Home Page

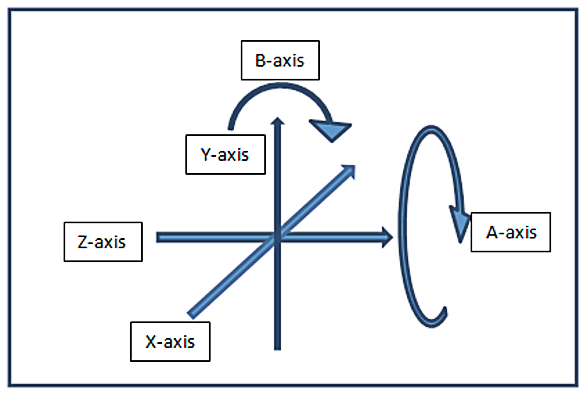

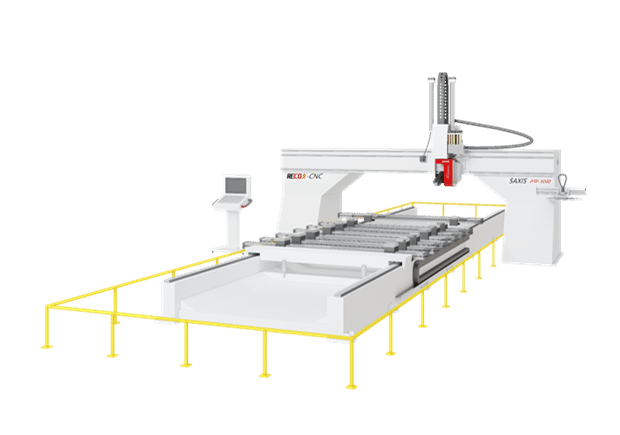

5 axis machining offers three linear axes and two rotational axes that work simultaneously to achieve complex surface machining.

A 5-axis machine helps you work on tighter tolerances to achieve complex geometries and allows you to hold your less complex parts in positions that allow better access to the features.

A 5-axis machine allows tools

to move simultaneously

around 5-axes of an object.

A 5-axis machine allows tools

to move simultaneously

around 5-axes of an object.

5-Axis machines utilize the typical X, Y, and Z-axes in conjunction with the A and B-axes so that your tools can get to five sides of a part, no extra turning or setup required.

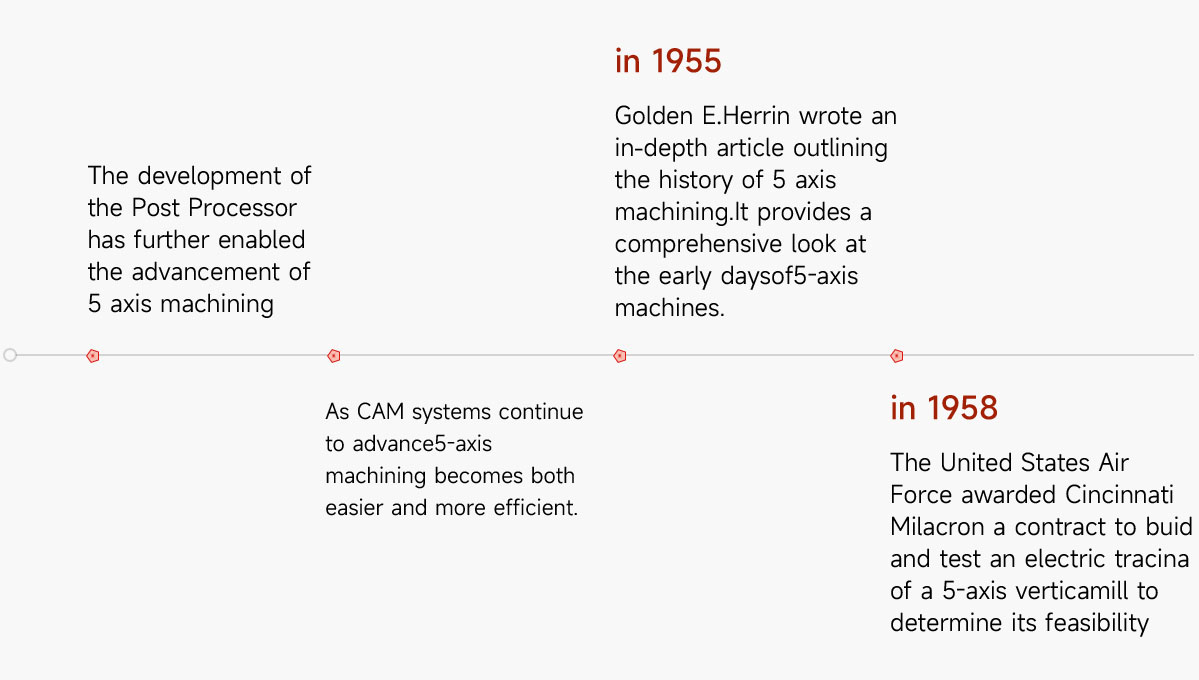

For years, machine owners have been adding additional components to upgrade their machine's efficiency and accuracy. While 5-axis may be a relatively new concept for some shops, using simultaneous multiple axes can be traced back to the late '50s and early '60s.

Over the last few decades, 5-axis advancements have made 5-axis machining centers as much of a reality as any vertical or horizontal machining center.Even from the start, the 5-axis process was so impressive it quickly developed into a crucial part of the US military, air force, and aerospace industries; and as technology and hardware progressed, its functions got easier to use, making the process more accessible.

Except of the clamped area and bottom of workpiece, the 5 axis CNC machine allows you working on every surface. A job will be finished in a single setup, so the production is saved and working efficiency is improved.

5-axis machining allows you to achieve complex shapes and designs.

For traditional 3 axis machine, you have to move the location of workpiece every time when one part of job is completed, prise alignment will be lost. Unlike 3 axis machine, 5 axis CNC machine allows you complete a job in single setup, a complicated design can be finished without loosing any precision.

Although 5 axis CNC machine is the best solution in many industries, but not every company has access to a 5 axis CNC machine, so by having one you have opportunity to provide your customers something your competitors can't, such as more delicate product, faster lead time, etc, which means your core competitiveness will be better than others.

The additional two axis, A axis and C axis, help you orient and bring the part closer to the cutting tool, which means a shorter cutting tools can be used, that will vibrate less, resulting in an improved surface finish.

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

GET QUOTE

Solid wood, chemical wood, plastic, ABS, PP/PE, fiber glass, EPS foam, carbon fiber, ceramics, gypsum, stone, aluminum, nylon, etc.

Solid wood

Solid wood Chemical wood

Chemical wood Fiber glass

Fiber glass Plastic

Plastic Carbon fiber

Carbon fiber ABS

ABS PP/PE

PP/PE Aluminum

Aluminum Ceramics

Ceramics Gypsum

Gypsum Industry plasticine

Industry plasticine EPS foam

EPS foam Nylon

Nylon Stone

StoneHere is reference information, including processing pictures of various fields.

Mould, crafts, blister, aerospace, automobile, sculpture, props, solid wood furniture, new composite materials, etcReady to start your automation journey? Have questions before getting started? We're here to help. Fill out the form below and a knowledgeable automation expert will be in touch.

Contact Us

Contact Us