Current Location:Home Page

At present, the traditional solid wood furniture industry is facing many problems, such as many kinds of wood, wood properties are difficult to control, often rely on experience; there are many special-shaped parts, equipment is difficult to reach, must rely on labor and so on. Compared with panel furniture, the linear and carving of solid wood furniture are more complex, especially Chinese classical furniture and Shanghai style furniture. The former contains 5000 years of Chinese carving texture, while the latter combines Baroque, Rococo and other beautiful and luxurious curves.

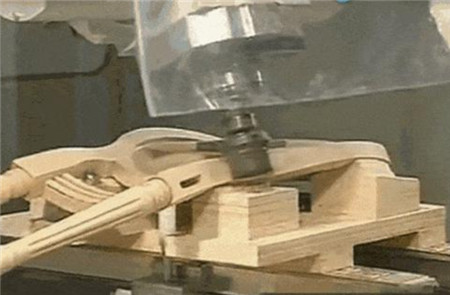

If the furniture is purely handmade, it will not only take a long time and high labor cost, but also almost rely on the experience of the craftsman. Through CNC woodworking machine tools, these exquisite textures can be edited into the tool path, and the rough embryo of furniture parts can be directly obtained, and then it can be refined manually, which is a qualitative improvement for the production speed of solid wood furniture enterprises.

RECOJI® CNC advocates machine replacement, replacing traditional labor with numerical control technology, getting rid of the dependence on labor, so as to reduce labor costs and improve production efficiency.

RECOJI® CNC Five axis machining center is mainly for various complex mortise and tenon, surface trimming, milling, drilling, slotting, chamfering, hollowing out, carving and other processes for 360 degree processing, five axis linkage molding.

Contact Us

Contact Us